Illuminating biomanufacturing. Enabling tomorrow’s biotherapeutics.

A flexible, next-generation Cell Line Development Platform for your biotherapeutics.

Our Photomolecular™ platform integrates advanced Optogenetic Cell Line Development technology with AI-driven bioprocess optimization for dynamic, tunable cellular control. By using light, we boost titers by up to 5-fold and unlock the production of difficult-to-express biotherapeutics, while also improving quality and consistency. Designed for flexibility and scalability, our solutions adapt to your manufacturing context, with expert collaboration and technical support at every step.

Whether due to host toxicity, short half-life, complex post-translational modifications, or secretion issues, we can address proteins that are difficult to express using three control levers:

- Light-mediated control of transcription allows temporal separation of cell growth and protein production, with tunable illumination parameters to identify the optimal expression regime for your complex biotherapeutics.

- Light-mediated control of secretory pathway genes relieves secretion bottlenecks to enhance production of your most complex therapeutic proteins.

- Light-mediated control over genes influencing post-translational modifications (PTMs) to match the desired critical quality attributes.

We enable lower-cost, higher-quality antibody manufacturing by maximizing titers, improving product quality consistency, and reducing cell doubling time. We have demonstrated up to a 5.6-fold increase in mAb titers relative to CMV controls. By driving down COGS and establishing a next-generation, flexible biomanufacturing process, we support product lifecycle management strategies that enhance market access and ultimately broaden patient access.

Our ongoing developments aim to combine high titers with precise alignment to innovator critical quality attributes. By applying light-inducible control over genes influencing post-translational modifications, we are working toward the ability to fine-tune PTMs in high-expression clones, enabling next-generation biosimilar development without compromising yield or quality.

Ongoing developments with our platform are focused on enabling precise control of subunit pairing in multispecific antibody formats and polyclonal approaches. By applying light-inducible regulation to balance chain expression and guide correct assembly, we are working toward reducing mispairing and achieving defined product compositions. These capabilities could unlock new avenues for producing complex biologics with greater fidelity, scalability, and quality.

Our technology has broad applications across biomanufacturing, including the development of viral vectors, disease models, nutritional proteins, and cultured meat.

A new infrastructure layer for biology.

Optogenetic CLD technology

We’ve developed high-performing optogenetic host cell lines and can enhance your existing cell line by integrating optogenetic systems, enabling precise, high-titer light-controlled gene expression.

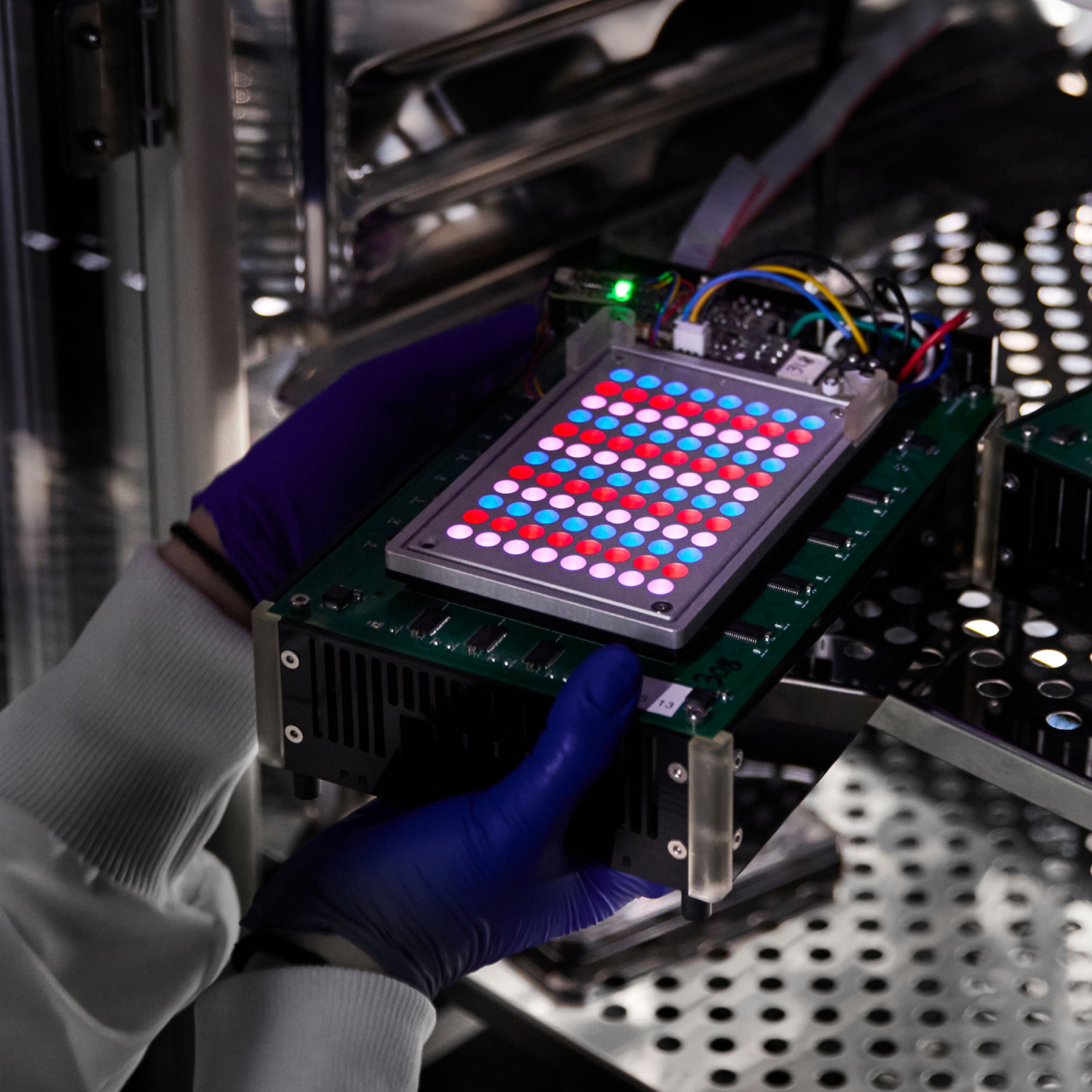

Illumination systems

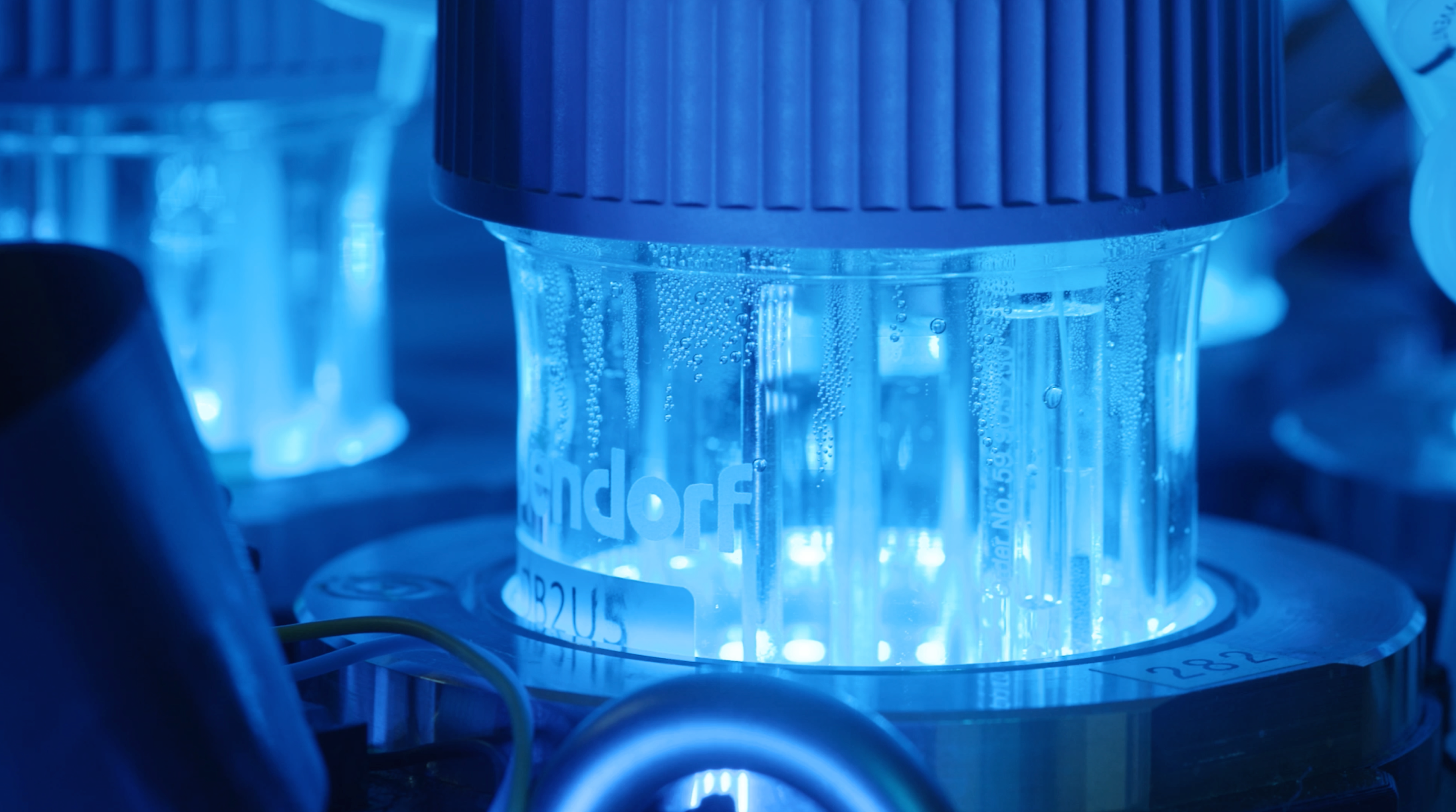

We can equip any bioreactor with light illumination, providing fast, flexible, and scalable biomanufacturing capacity.

AI-Driven Bioprocess Optimization

Our smart control system continuously monitors and adjusts illumination in real time. We leverage real-time process data and ML models to dynamically adjust light, maximizing yield and product quality.

Custom solutions: Our light control and genetic constructs interact directly with your biology.

We can precisely control any cellular function in any cell type by activating photosensitive receptors. When met with the right wavelength of light, these protein switches come together.

Our technology solves developability and COGS challenges in biotherapeutics production.

Prolific approach

Standard approach

Decouple cell growth from protein production

Prolific approach

Maximize titer and quality by tuning expression

Prolific approach

Control Post-Translational Modifications to match desired CQAs

Custom Solutions. Multiple Possibilities.

Do you have a biotherapeutic protein with titer, developability, or COGS challenges? Contact us for a discovery meeting.

Recent News

Prolific Machines Selected to Join FDA's Emerging Technology Program, Advancing the Company’s Novel Biomanufacturing Platform

Prolific Machines Appoints Former Catalent Chief Scientific Officer to Board of Directors

Prolific Machines Announces the Completion of Optogenetic Bioproduction at 200L, Marking the World’s Largest Demonstration of Optogenetics to Date

FAQs

Our Photomolecular platform brings together optogenetic cell line development technology, illumination systems, and AI driven bioprocess optimization to precisely control and optimize cellular behavior to more efficiently produce superior biotherapeutics.

Methods currently used to make biotherapeutics are limited to imprecise, inefficient, and expensive control levers, like temperature, chemicals, and proteins to indirectly control cells. Prolific’s platform brings together safe and effective tools to unlock unparalleled, direct control, and precision.

Living organisms have the ability to sense light because of light sensitive proteins (LSP). These naturally occurring proteins are found everywhere, from plants and bacteria to human retinas, and exist to detect and respond to light. They can do this very quickly to cause action in cells within seconds.

Proteins are at the heart of everything a cell does, from perceiving signals from other cells to switching genes on or off. By attaching LSPs to proteins that you want to control within the cell, Prolific makes it possible to precisely control subcellular biology using light. When met with light, which acts as a signal, these LSP can precisely control key functions within cells.

Prolific unlocks dynamic control by pulsating light in specific patterns, intensities, and wavelengths to activate cellular functions when and where it matters most, which is a gamechanger for biomanufacturing.

We’re co-developing the future of biology with innovators and leaders across biopharmaceuticals and advanced nutrition. Examples include proteins found in supplements and infant formula, antibodies to treat diseases, whole cuts of cultured meat, higher fidelity disease models, and other innovations never before possible.

Yes, safety is a key benefit of our platform. Consistency is also a major advantage, which further increases the safety of our technology and process. Light is an abundant, highly controllable, and predictable input that has played a role in cellular control in countless organisms since the dawn of time.

Our process uses light, which acts as a signal to control the light-sensitive proteins (LSP) and direct cellular behavior. We procure these from a wide range of natural sources, including widely consumed plant foods like cabbage, mustard greens, and spirulina.

We use ‘non-ionizing’ light at relatively low intensities in our process, which means it doesn’t carry enough energy to harm living cells. It is safe for use in the production of biotherapeutics.